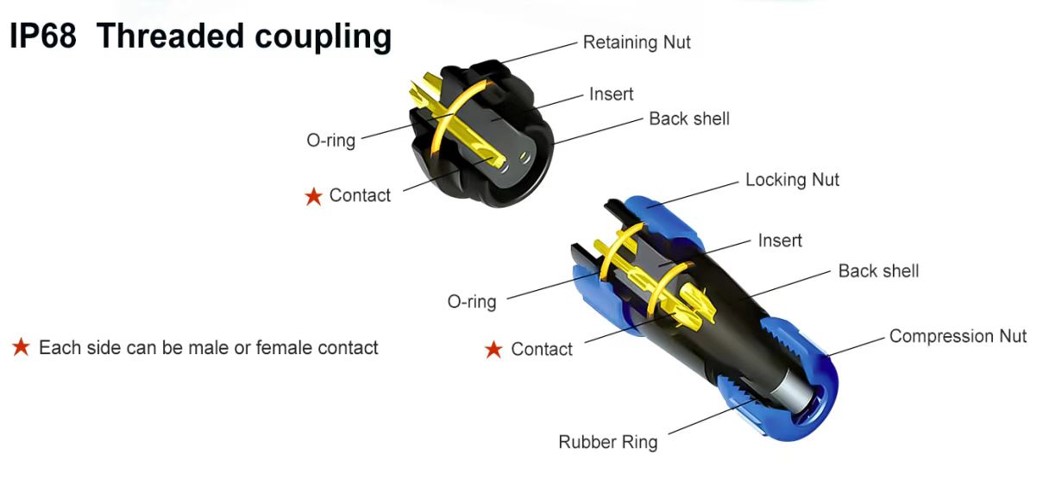

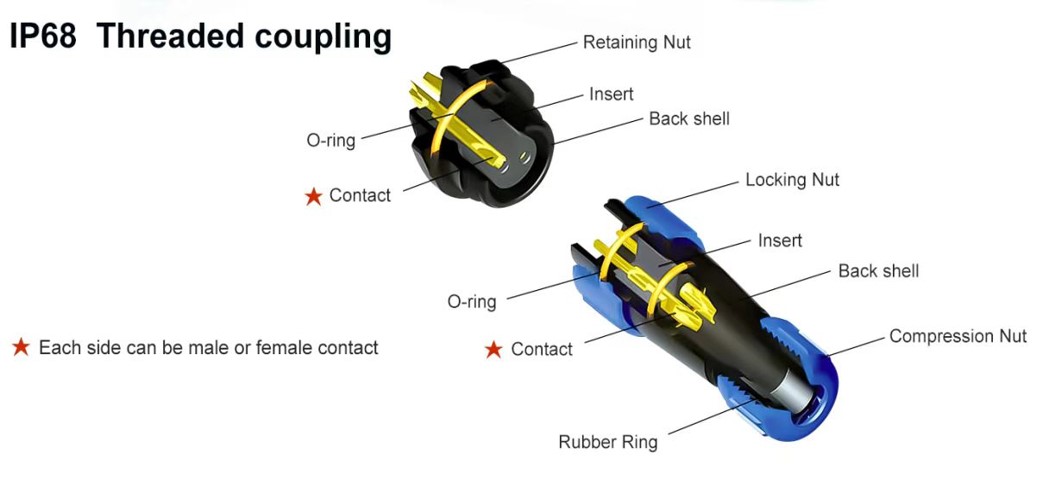

Connector head and socket options: male and female connector heads and female and male socket options;

Number of cores: SP11 connectors offer 2-core, 3-core, 4-core, and 5-core options to accommodate different working currents and application needs.

Waterproof rating: SP11’s waterproof rating is IP67, which means it can prevent dust from entering and withstand brief submersion in water.

Wire welding service: customers can weld their own wires according to their actual needs, and if customers have the need, FREMI can also provide welding wire services.

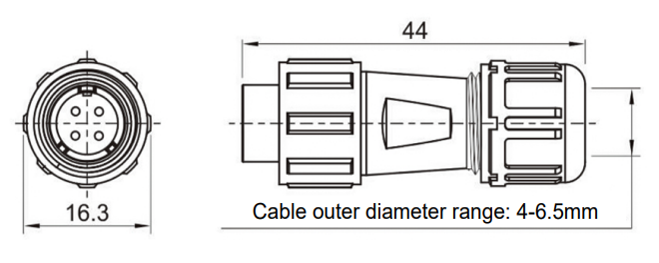

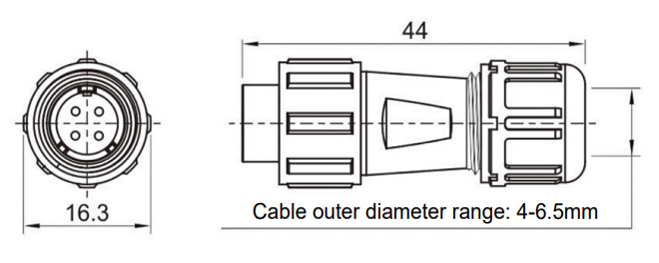

Materials and technical parameters: SP11 connectors use threaded locking, the shell material is thermoplastic PC and PA66, the flame retardancy rating is V-0. The insulator is thermoplastic PPS, which can withstand high temperatures up to 260°C. The contact material is copper plated with gold, ensuring good electrical conductivity and corrosion resistance. SP11’s wiring methods include welding, and the cable diameter range is I: 3-4mm and II: 4-6.5mm.

In summary, SP11 connectors offer a variety of core options to meet the needs of different application scenarios, have a high waterproof rating, and can provide wire welding services according to customer needs.

13928445752

13928445752